Screw barrel manufacturer

- OEM Replacement Ready • Bimetallic Options • Up to 315″ One-piece Length

- Engineered for GF / ABS / PC / PA66

- Standard orders delivered in 30–45 days.

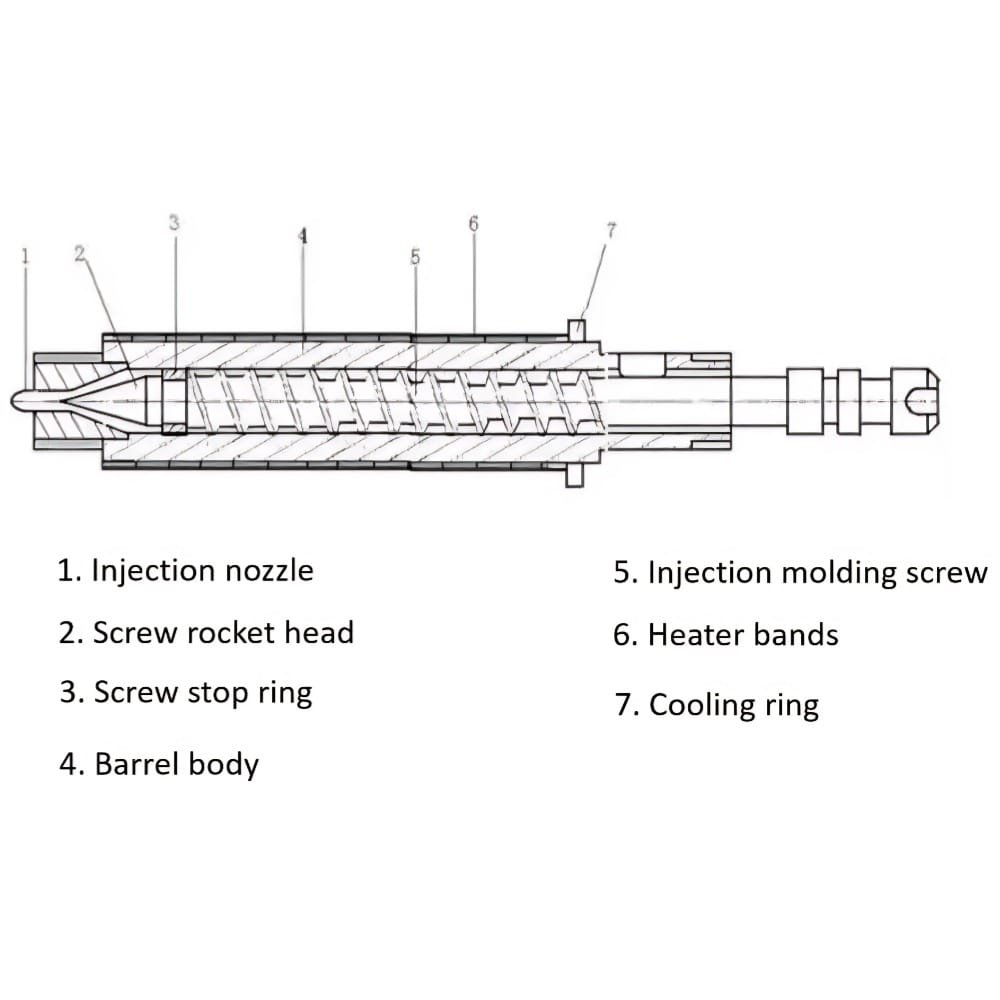

Our Screw Barrel Specifications

Send us your machine brand or drawing — we’ll ensure precise compatibility.

Suitable Machines: Nissei, Toshiba, Sumitomo, Demag, Engel, Fanuc, Haitian, FCS, Welltec etc.

Sintered Screw Barrel

- HRC 65 Wear Resistance

- Custom by Drawing or Sample

- Fits Ø18–300 mm Machines

- Resists Glass-Filled Materials

Injection Barrel

- Fits 50–1000T machines

- Withstands 300MPa pressure

- Mounting tolerance ≤0.02mm

- HRC 58–65 hardness

Injection Screw

- 3M cycles wear resistance

- Diameter 16–150mm

- Fits 50–1500T machines

- Custom single/twin flight

Rubber Screw Barrel

- Dia. 36–250 mm available

- For NBR/EPDM/SBR rubber

- Hardness up to HRC 60

- Single/twin flight optional

PTA Bimetal Screw

- 1.5mm PTA bimetal layer

- HRC hardness up to 65

- 3–5× service life

- Resists GF and fillers

PVD Coated Screw

- PVD layer 2–6μm thick

- Low friction, μ≈0.3

- Hardness up to HV3300

- Resists heat and corrosion

Material Composition

Constructed using 38CrMoALA nitrided steel with optional bimetallic surfacing, reinforced by Ni-based alloy and Tungsten Carbide (WC) for superior wear and corrosion resistance in high-load injection applications.

| S/N | Product Name | Basic parameters | Application | Composition and process |

|---|---|---|---|---|

| 1 | HK1 Iron Base Bimetallic Barrel | 1. Hardness (HRC): 58-62 2. Wear resistance:★★★★ 3. Corrosion resistance: ★★★ 4. Temperature range (℃):≤400 | Low-viscosity wearproof resins General-purpose resins and engineering resins with glass fiber content below 35%, including PP、PA、ABS、POM、PBT、PC. | Alloy composition: C, Mn, Si, B, Ni, Fe,Cr |

| 2 | HK2 Iron Base Bimetallic Barrel | 1. Hardness (HRC): 64-69 2. Wear resistance:★★★★ 3. Corrosion resistance: ★★★★ 4. Temperature range (℃):≤400 | Performance advantages: High wear resistance Application: General purpose resins and general engineering resins. PP, PA, LCP, PPS, PPA, POM, PBT, PC with less than 50% glass fiber. | Alloy composition: C, Mn, Si, B, Ni, Fe, Mo, Cr |

| 3 | HK3 Nickel Base +35% Cobalt Bimetallic Barrel | 1. Hardness (HRC): 52-56 2. Wear resistance:★★★★★ 3. Corrosion resistance:★★★★★ 4. Temperature range (℃):≤400 | Application: high temperature resistance resins with iron powder, ceramic powder, aluminum magnesium powder, magnetic powder, copper powder and others. | Alloy composition: W, Cr, B, Ni, Co |

| 4 | HK5 Nickel Base +25% Tungsten Carbide Bimetallic Barrel | 1. Hardness (HRC):50-56 2. Wear resistance:★★★★★★ 3. Corrosion resistance:★★★★★★ 4. Temperature range (℃):≤500 | Application: Suitable for wear resistance and corrosion resistance special engineering resin. PP, PA, LCP, POM, PPA, PBT, PPS, PEI, PEEK, PA46, LCP, HTN with less than 50% glass fiber. | Alloy composition: W, Cr, B, Ni |

| 5 | HK6 Nickel Base +45% Tungsten Carbide Bimetallic Barrel | 1. Hardness (HRC):58-62 2. Wear resistance:★★★★★★ 3. Corrosion resistance:★★★★★★ 4. Temperature range (℃):≤600 | Application: Suitable for wear resistance and corrosion resistance special engineering resin. PP, PA, LCP, POM, PPA, PBT, PPS, PEI, PEEK (halogen free materials: PA46, LCP, 4T, 9T, HTN) with less than 65% glass fiber. | Alloy composition: W, Cr, B, Ni |

| 6 | HK7 Nickel Base +45% Spherical Tungsten Carbide Bimetallic Barrel | 1. Hardness (HRC):60-65 2. Wear resistance:★★★★★★★ 3. Corrosion resistance:★★★★★★ 4. Temperature range (℃):≤600 | Application: Suitable for special high glass fiber ultra-halogen-free raw materials: 4T, 9T, HTN, DSM, PSM and various acidic plastics with high corrosion. | Alloy composition: W, Cr, B, Ni |

4 Reasons to Choose Us

Precision-crafted for global injection and extrusion machines.Trusted by manufacturers in 60+ countries for reliability and performance.

1. 99.3% Machine Compatibility

We manufacture screws and barrels compatible with 100+ machine models worldwide, including Haitian, JSW, Toshiba, Engel, and KraussMaffei. With over 20 years of experience as an original supplier for Toshiba screw and barrel assemblies, we bring proven expertise in dimensional accuracy. Whether you provide a drawing, a worn sample, or just your machine model, we deliver precise fit and seamless installation every time.

2. Superior Wear Resistance

All components are made using high-grade materials such as PTA-hardened layers, bimetallic alloy linings, and optional PVD coatings. These technologies significantly enhance resistance to wear, corrosion, and glass fiber abrasion — delivering 2–5x the service life of standard screws in demanding production environments.

3. Fast Delivery & Flexible MOQ

With in-house machining and a stable supply chain, we can deliver standard items within 7–10 working days. For urgent needs, rush production and sample testing are available. We accept small-volume orders starting from 1 set, making us ideal for both OEMs and equipment repair shops.

4. Engineering Support Included

Our engineers offer end-to-end support — from selecting the right steel grade to adjusting L/D ratio or flight design for better performance. Whether you're replacing worn parts or optimizing for new materials, we provide professional advice to ensure your machine runs smoothly and efficiently.

Fits 20+ Machine Brands

Engineered to match popular machines like Haitian, ENGEL, JSW, KraussMaffei, Nissei, and more — with guaranteed 100% fit.Suitable Machines: Nissei, Toshiba, Sumitomo, Demag, Engel, Fanuc, Haitian, FCS, Welltec etc.

Get Support Anytime You Need

Get your quote within 24 hours — backed by 1-on-1 engineering support for screw & barrel selection, customization, and delivery coordination.

About iHome Screwbarrel

With over 20 years of precision manufacturing, iHome Screwbarrel delivers 500,000+ units annually to global clients. Our factory spans 12,000㎡, housing 60+ CNC machines and 5 dedicated heat treatment lines to meet any scale of order.

Each screw and barrel undergoes 8 quality control stages, with 100% precision testing before shipment. We maintain a <0.3% return rate and a 98% on-time delivery rate, ensuring worry-free global partnerships.

100 % Machine Fit Guaranteed

We don’t just promise a fit — we engineer it.

Here are five solid reasons our screws & barrels match your machine perfectly the first time.

- 20+ years of reverse engineering for 100+ models.

- Match any size or brand with ±0.01 mm precision. Just send us your specs.

- Chances are, we’ve already built for your machine — no trial-and-error.

- Every unit checked for tolerance, heat treatment, and fitting simulation.

- Trusted by 80+ Buyers in 30+ Countries

Six Key Stations That Guarantee Your Quality

You don’t see what happens behind the scenes — but that’s where your quality is guaranteed. Here’s how we make it happen.

01 Column Boring & Cylinder Line

Large-scale boring and turning ensure perfect straightness and internal finish for all barrel bodies, even up to 3 meters long.

02 Screw Production

Line

Full-process screw manufacturing — from rough shaping to flight grinding — supports 1:1 customization for over 100 machine types.

03 Heat Treatment – Nitriding & Quenching

Our dual nitriding and tempering processes boost wear resistance and thermal stability across demanding molding environments.

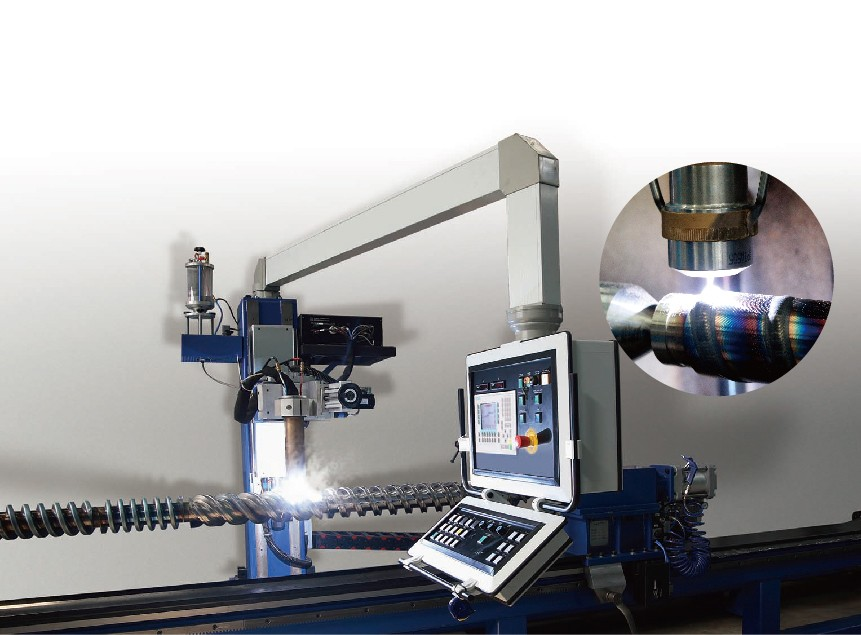

04 PTA Welding & Hardfacing Zone

Advanced PTA overlay welding adds bimetallic wear-resistant layers to flight edges and inner barrels, extending service life 2–3X.

05 Quality Control

Center

3D CMM, thread pitch scanners, and concentricity tests ensure every piece meets strict tolerances before packaging.

06 Final Assembly & Warehouse

Pre-assembled parts are stored and ready to ship, supporting short lead times for both regular and custom orders.

Our Customization Process

We provide 1:1 customization based on your drawings, samples, or specifications — ensuring precise fit and reliable performance.

- Step 1: Send us CAD files, technical specs, or old parts.

- Step 2: Our team verifies dimensions, structure, and material needs.

- Step 3: You receive a detailed quote within 24 hours.

- Step 4: Production starts after confirmation of all technical details.

- Step 5: Each part goes through full inspection before shipment.

- Step 6: We ship globally and support installation if needed.

Hello, I’m Lydia – Your Screw & Barrel Expert

With 10+ years in precision machining and fitment analysis, I help B2B buyers select the right screw barrel that fits perfectly the first time – reducing downtime, saving cost, and simplifying sourcing decisions.

Trusted by Global Buyers from 30+ Countries

Over the past decade, we’ve welcomed hundreds of overseas clients to inspect our products and verify compatibility. Every photo is a real moment — not just a handshake, but a proof of trust and successful cooperation.

300+ Verified Projects Delivered

99% Replacement Fit Rate

80+ OEM Screw Models Replaced

30+ Countries Served Worldwide

What Our Happy Clients Say

Real feedback from real buyers. From machine matching to on-time delivery, we earn trust one message at a time.

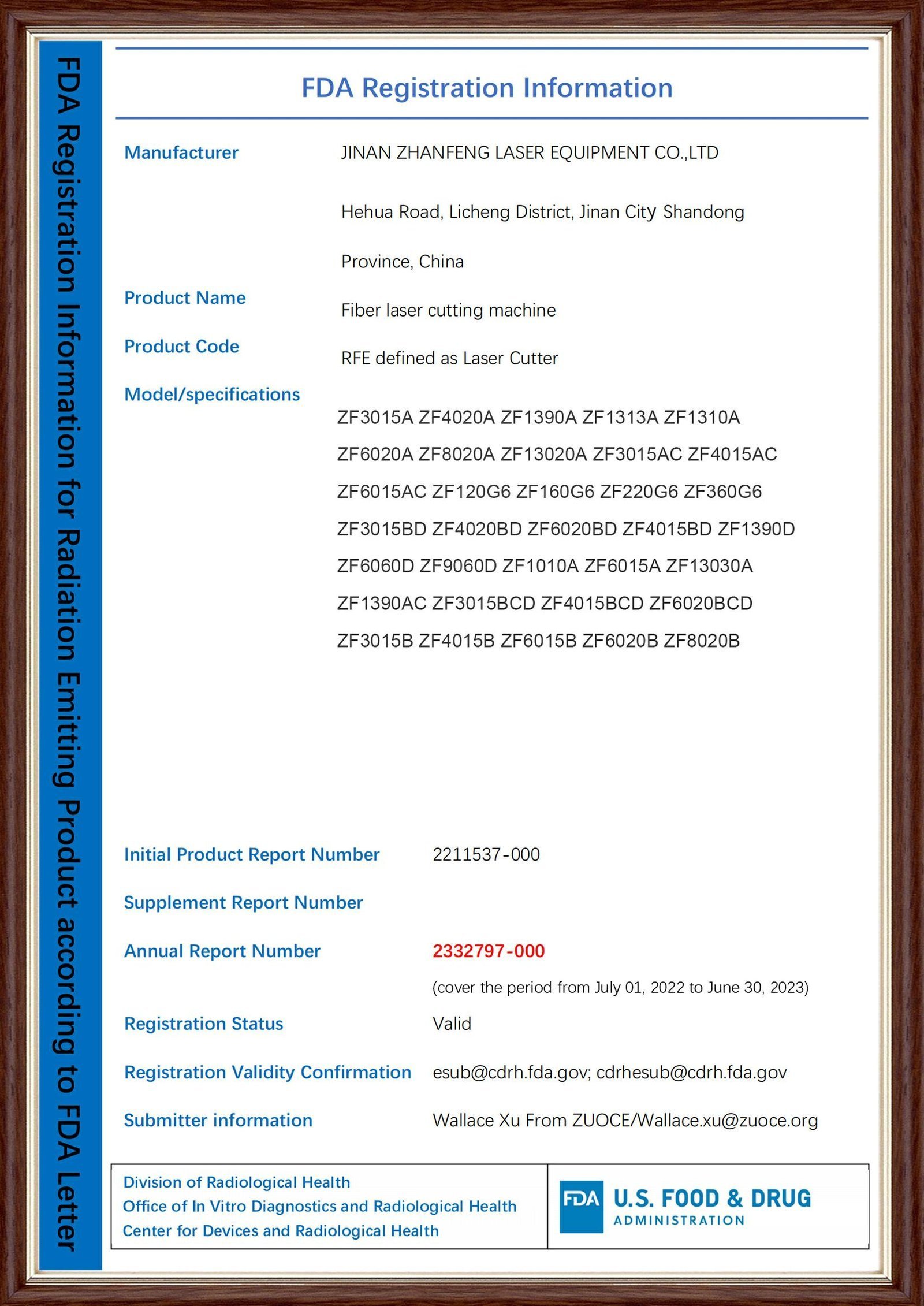

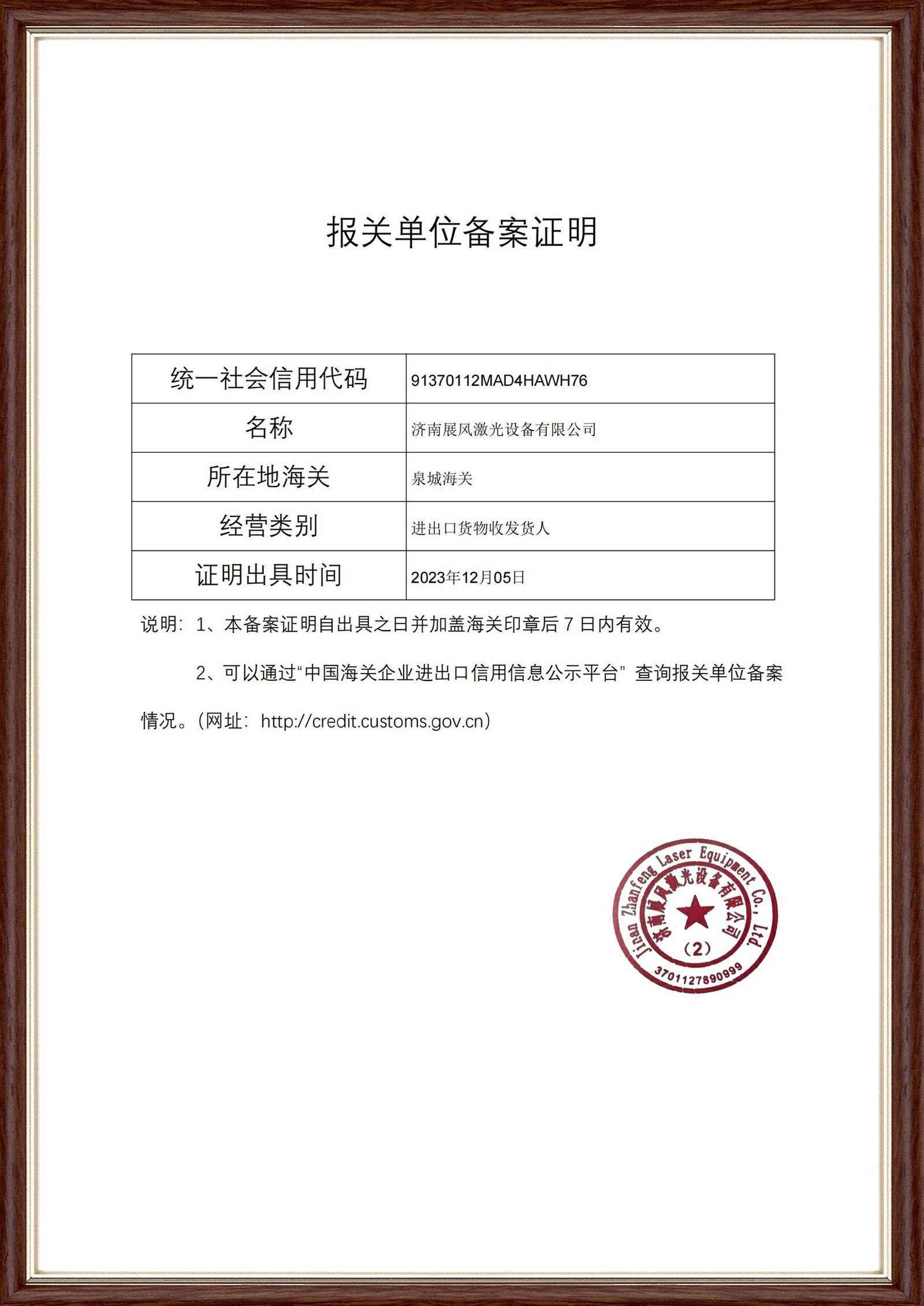

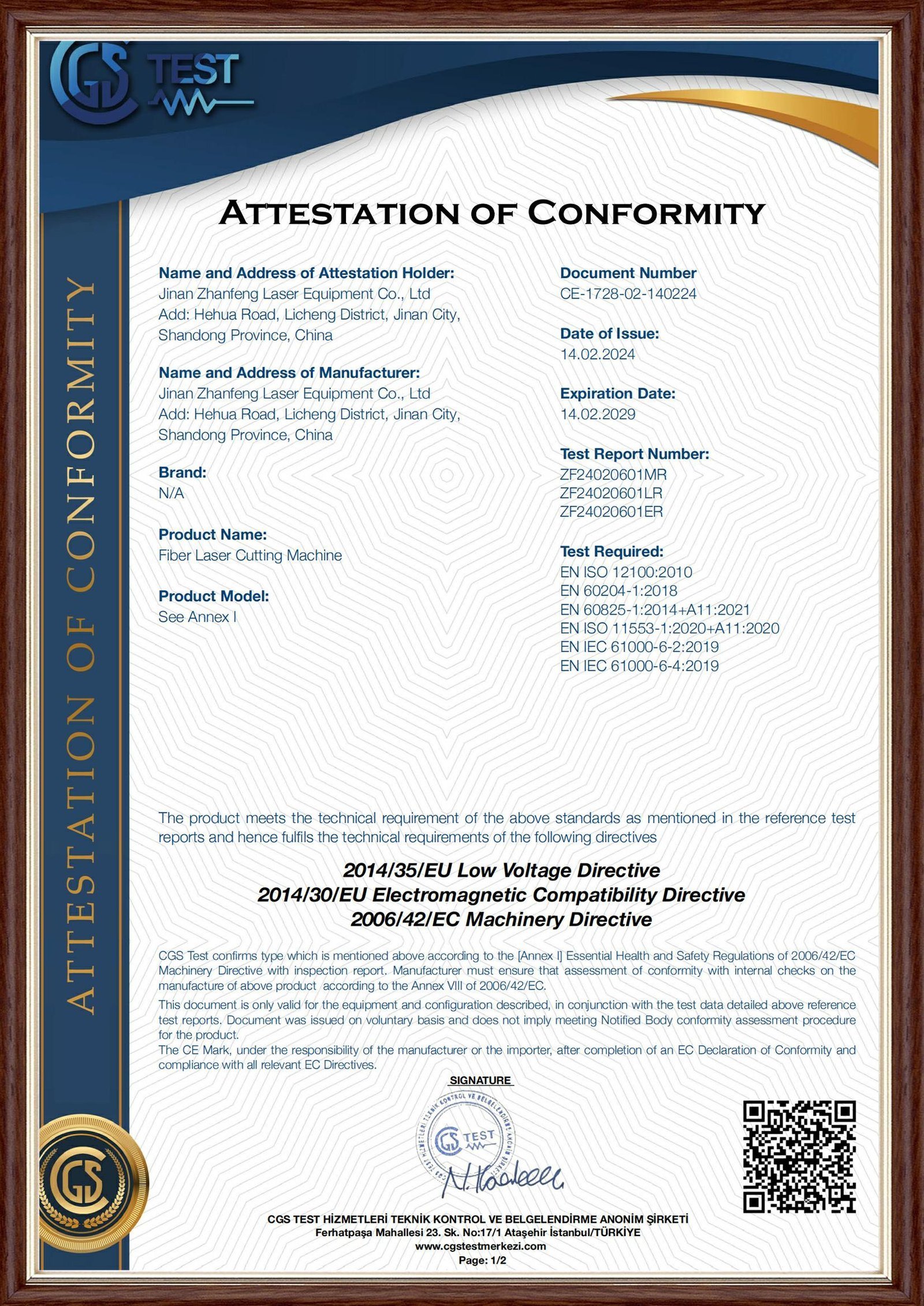

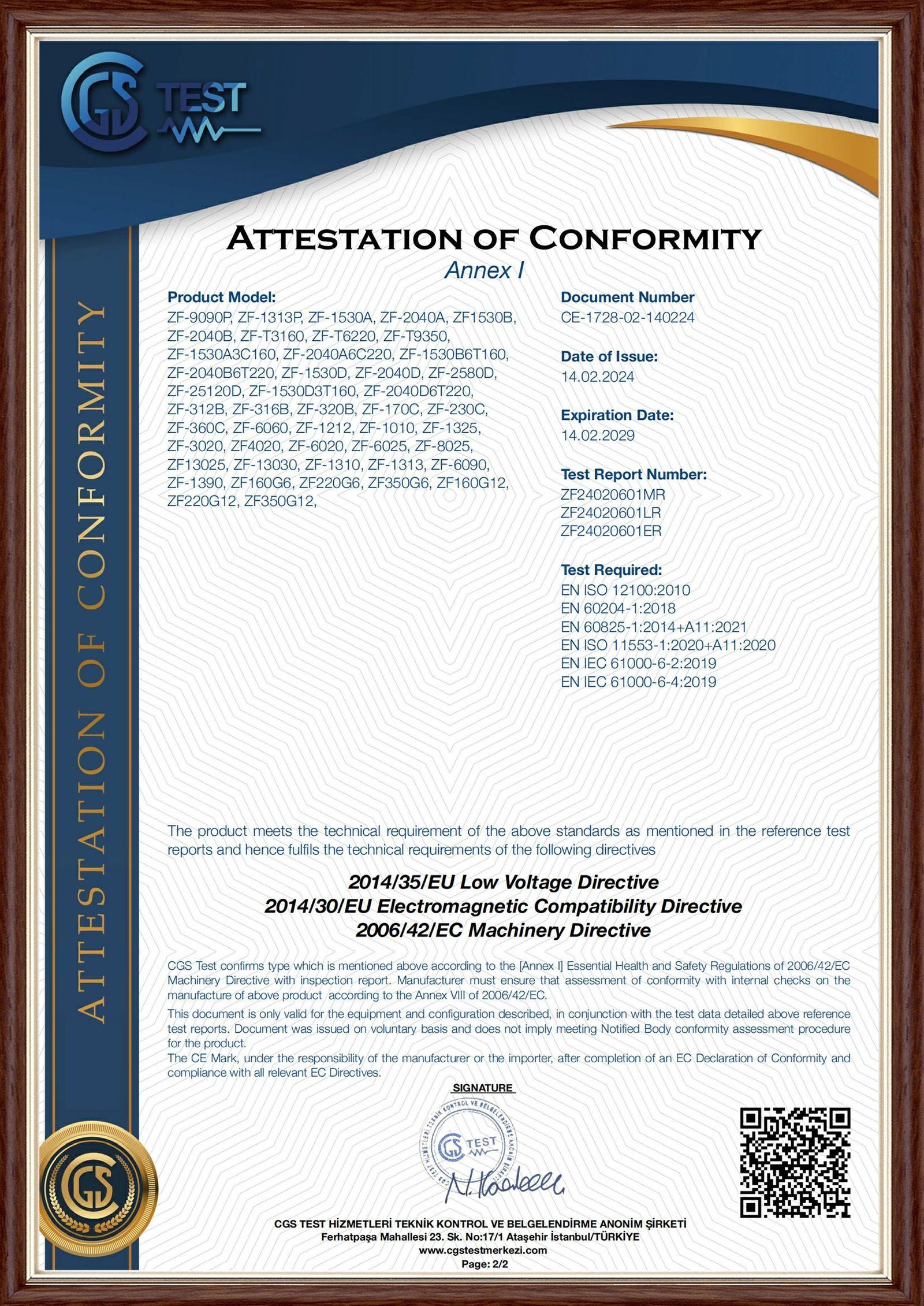

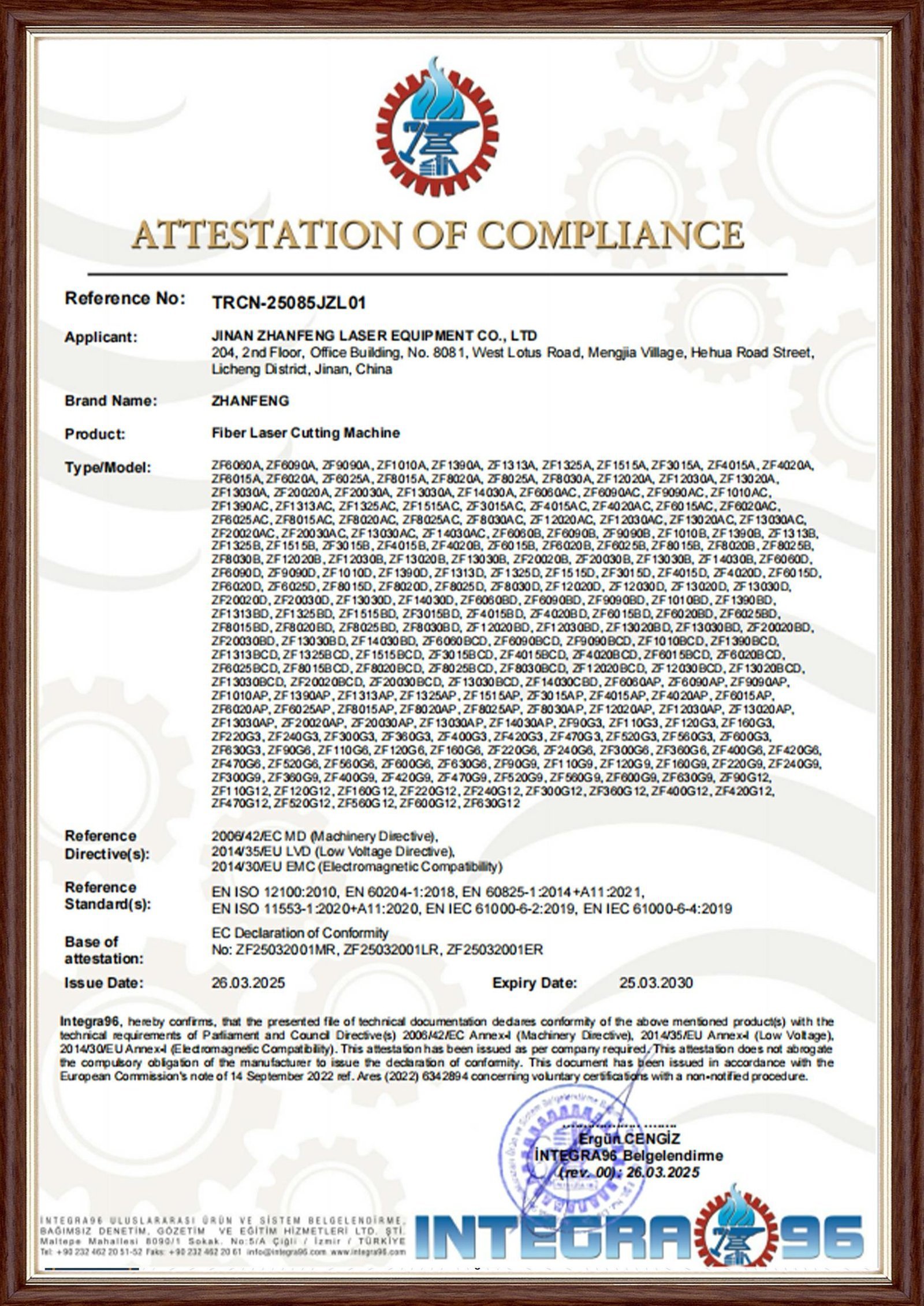

Certification

Our machines have passed CE and FDA certifications to meet the import requirements of customers in various countries.

Quick Buyer Q&A

We have listed some questions you may ask. If you have more inquiries about our products, you can send an inquiry to contact us.

Yes. We support 100+ global brands like Haitian, JSW, ENGEL, Toshiba, and more. Just send your machine model or drawing.

We can work from CAD drawings, used samples, or basic specs (L/D ratio, diameter, flight depth). We ensure 99% match.

Standard orders take 30–45 days depending on quantity and custom complexity. Urgent orders can be prioritized.

Yes. All screw barrels are QC-certified with full inspection reports. Warranty available on request. requirements of different construction projects.

Need a Matching Replacement?

We support 100+ machine brands. Share your specs or damaged sample—we’ll deliver 99% compatible replacements with zero-fit issues.

Start Your Custom Screw & Barrel Order

Tell us your machine model, drawing, or sample info. Our engineers will confirm fitment and send you a detailed quote within 24 hours.

Email:info@ihomescrewbarrel.com